JK Wrangler Duroflex Control Arms, Full Set

MetalCloak JK Wrangler Duroflex™ Control Arms represent one of our best innovations in suspension components. Our Patented (mcpatents.com) Duroflex Joints are designed to stay centered and aligned to the frame and axle for the best, long term, performance.

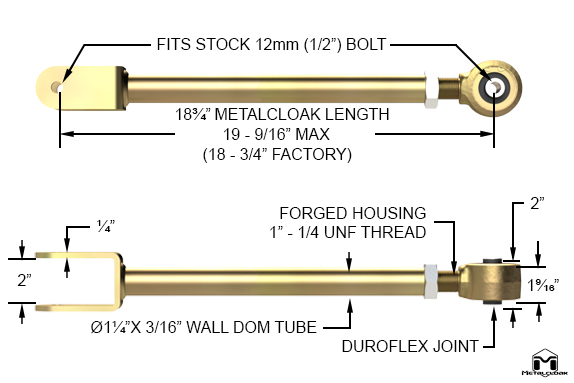

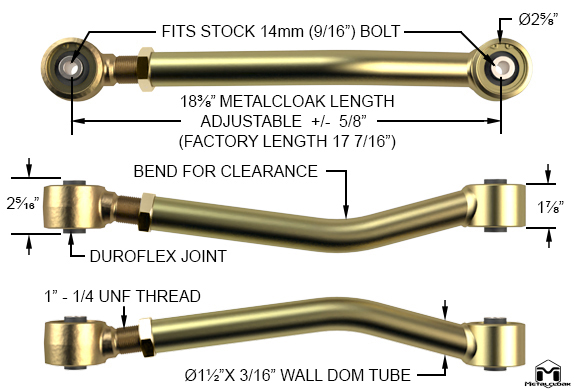

Features Include:- CNC formed 1 1/2" .187 DOM Steel Upper Control Arms

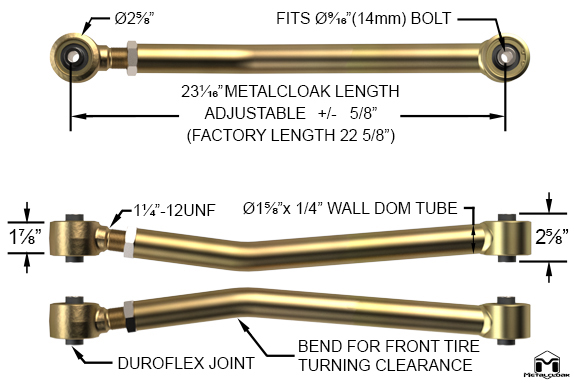

- CNC formed 1 5/8" .25 DOM Steel Lower Control Arms

- Adjustable Forged Threaded Ends

- High Clearance Bends

- Duroflex™ Joints Enhanced with Kevlar

- Vibration Dampening & Self Centering (best ride quality)

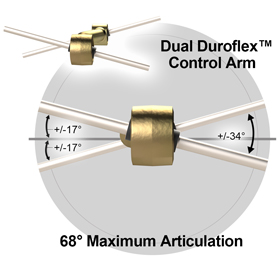

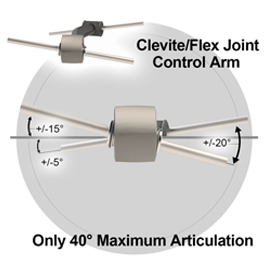

- 68° of Maximum Articulation (typical arms only 40°)

- Maintenance Free and Easily Rebuildable

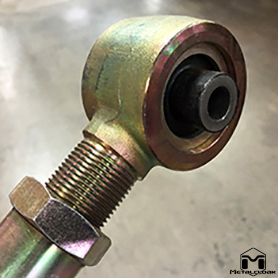

- Gold Zinc Plated for Protection Against the Elements

- Designed for Maximum UP and DOWN Travel

Fitted with Duroflex™ Joints, the only vulcanized elastomer, self-centering joint enhanced with DuPont™ Kevlar® fiber – providing incredible durability with more misalignment in the control arms and better vibration dampening than anything else available. Exclusive to MetalCloak (see detailed info in the main body).

MetalCloak “components” have been proven safe with the FMVSS certificate of safety configured with 37" tires, full body armor and suspension lift.

[click for less...]

VIDEOS

MetalCloak's Jeep JK Wrangler Suspension Components are second to none.

Who Is MetalCloak?

MetalCloak creates Game-Changing Products for the Off Road Enthusiast.

JK Wrangler Duroflex Control Arms

MetalCloak JK Wrangler Duroflex™ Control Arms represent one of our best innovations in suspension components.

Duroflex 101

This short video covers what you need to know about the basics of the Duroflex Joint. How it should be used and what to expect when using it.

Why Gold Zinc?

It's time for The MetalCloak Minute... where we answer frequently asked questions in about a minute. Today's topic: Gold Zinc.

Duroflex Joint Maintenance

It's time for The MetalCloak Minute... where we answer frequently asked questions in about a minute. Today's topic: Joint Maintenance

Duroflex Joint Revealed

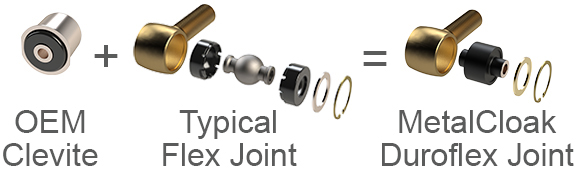

The MetalCloak Duroflex Joint gives better dampening properties over OEM style rubber Clevite Joints and provides more misalignment than “other” inferior Flex Joints.

Vibration Dampening

We tested our Duroflex Joint using a "Shaker Table" and seismometer app to show how much Vibration Dampening the Duroflex Joint gives you compared to other industry leading joints.

A Comparison of Flex

Comparing the Flex of the Duroflex Joint with that of the Johnny Joint, the Teraflex Monster and the typical Clevite.

What is Corner Travel Index?

Since 2014 MetalCloak has tested thousands and thousands of rigs at events all across the county collecting specs on the build and cataloging the results. The data collected allows us to make our own products better.

FMVSS 126 Compliant

MetalCloak not only has the best off road flex, but we are also Federal Motor Vehicle Safety Standard 126 certified and compliant. No other company can match our on- and off-road performance.

THE TECH

IT ALL STARTS WITH THE BUSHINGS

The Patented Duroflex™ Joint ( metalcloakpatents.com) is the key to getting the greatest flex in a bolt-on suspension kit. Period.

MetalCloak has taken the best features of the most widely used control arm joints and combined those features to create the Duroflex Joint, producing a Low-Maintenance, High-Misalignment (34˚), Self-Centering, Rebuildable Joint with an OEM quality ride.

Now with Kevlar!

DuPont™ Kevlar® Fiber is now compounded in the proprietary elastomer of the Duroflex Bushing, bringing even more strength, durability and performance.

Kevlar® is a synthetic fiber with extremely high tensile strength to weight ratio…five times stronger than steel and commonly used in bullet proof armor applications.

Duroflex Bushings w/Kevlar® can be identified by the MetalCloak “M” located on the outer surface.

The Duroflex Joint Provides The Best Ride. Period.

Made of a Proprietary Elastomer Compound, the High Vibration Dampening and Self-Centering characteristics of the Duroflex Joint means you will always get...

- The best ride quality

- No binding of your control arms.

- None of the micro-wear that DESTROYS Flex Joints

High Misalignment...

By adapting the High Transverse Flex characteristics of a typical Flex Joint, the Duroflex Joint gives you...

- Over 34° of Misalignment

- Over 68° per Control Arm

Absorbs Micro-Movements...

Because the Duroflex Bushing absorbs the millions of Rotational Micro-Movements found in your daily driving, you get...

- Improved Ride Quality

- None of the micro-wear that DESTROYS Flex Joints

True Bearing Surface...

The outer surface of the Duroflex Bushing acts as a bearing, breaking free when called for, giving you...

- Maximum Rotation & Articulation

- No "Binding Up" of the Control Arms

Low Maintenance & Rebuildable...

Unlike typical Flex Joints, the Duroflex does not require replacing key parts every year like others...

But, when you do need to rebuild it, it is MetalCloak Easy!

Just pull out the Duroflex Bushing, clean it up, add some new Teflon impregnated, synthetic silicone grease. Reassemble.

Done.

Forged for Strength...

The adjustable threaded ends are Forged providing a 37% higher fatigue strength over inferior cast parts, this EXTRA rock bashing strength will hold up to whatever you throw at em.

At MetalCloak We Take The Care To Build It Right...

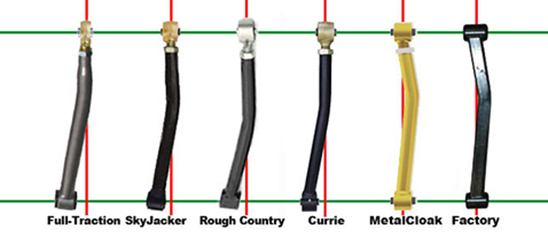

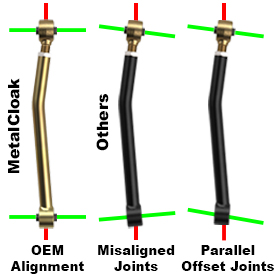

Control Arm Duroflex Joint Alignment...

At MetalCloak we take the care to build every product right.

Most manufacturers build their control arms misaligned from center. Why? It simply costs less to do so.

By not cutting any corners, our joints are Centered and Aligned reducing wear and improving performance.

It makes them easier to install, too!

Control Arm Specs

- CNC Formed

- 1/4" Wall DOM Steel

- 1.625" OD

- Threaded Forged Ends

- Precision Locking Nut

- Gold Zinc Plated

- Duroflex Joint at Both Ends

- CNC Machined

- 3/16" Wall DOM Steel

- 1.25" OD

- 3/16" Steel Clevis

- Precision Locking Nut

- Gold Zinc Plated

- Duroflex Joint

- Threaded Forged Ends

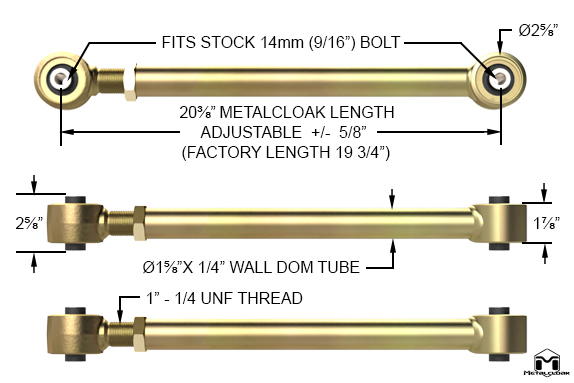

- CNC Machined

- 1/4" Wall DOM Steel

- 1.625" OD

- Precision Locking Nut

- Gold Zinc Plated

- Duroflex Joint at Both Ends

- Lengthened 5/8" for Best Axle Position

- Threaded Forged Ends

- CNC Formed

- 3/16" Wall DOM Steel

- 1.5" OD

- Precision Locking Nut

- Threaded Forged Ends

- Designed for Oversize Tire Clearance

- Gold Zinc Plated

- Duroflex Joint at Both Ends

- Lengthened for Best Axle Position

Degrees of Articulation

MetalCloak's Duroflex Joint provides 28˚ more articulation and flex than typical control arms! (Learn More About Duroflex Control Arms)

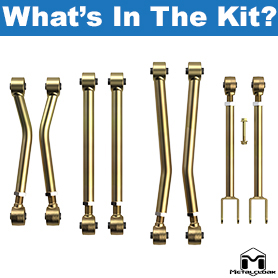

What's In The Kit?

- Upper Front Control Arms

- Lower Front Control Arms

- Upper Rear Control Arms

- Lower Rear Control Arms

- All Required Hardware

TECHNICAL SPECIFICATIONS

| Items | Details |

|---|---|

| Compatibility | 2007 - 2018 Jeep JK Wrangler |

| Control Arms | 1 1/2" x .187 DOM Steel Tubing 1 5/8" x .25 DOM Steel Tubing |

| Duroflex Joint | Proprietary Vulcanized Elastomer made with DuPont™ Kevlar® fiber |

| Steel Coating | Gold Zinc |

INSTALLATION

| Installation Difficulty | Moderate |

| Body Modification | None |

| Time to Install | 2 - 3 Hours |

| Installation Instructions | Click Here to see a full list of MetalCloak Installation Instructions. |